Ceramic PCB has been widely chosen in power electronics, hybrid microelectronics, electronics packaging and multi-chips module due to its tasty performance on heat conductivity and gas tightness.

Ceramic Substrates Types and Features

Among these years ceramic PCB are generally made by four manufacturing technologies: HTCC, LTCC, DBC and DPC.

HTCC is initially commonly used to make ceramic circuit boards. It requires, as its name suggests, ultra high temperature in sintering and only a few options of electrode materials selection. So the manufacturing cost, on all aspects, are high and LTCC technology is invented very soon. However, though LTCC only need 850 centigrade on sintering but the final ceramic PCB are low tolerance in size of boards and circuits, and its own strength.

DBC and DPC are both mature ceramic PCB manufacturing technologies in recent years. DBC technology bind AL2O3 and Cu plate directly with high temperature. The restriction goes to the micro air hole between two plates which made the circuit boards with in consistent quality on batch production.

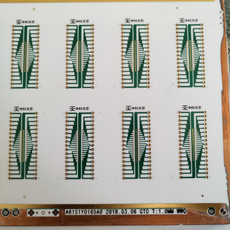

DPC is to plate copper directly on the AL2O3 plate (ALN too), which is the most common technology in Chinese manufacturers of cermic boards. However it requires relatively high technology on both theoretical and practical, so there is a hidden barrier to enter the DPC family.

Heat conductivity

Heat conductivity defines a substrate ability to conduct/dissipate heat. The number goes higher, the heat is conducted quicker and better. In the field of LED ceramic PCB, the main topic is how to conduct heat from chips to overall enviorment to reduce chip temperature, thus to increase luminous efficiency and working hours. So, to choose the right substrate is most important choice on LED project.

AL2O3, itself, heat conductivity is 20-24. But in the manufacturing technology of LTCC to reduce its sintering temperature, 30%-50% fiberglass is mixed into AL2O3 and its compound heat conductivity reduce to 2-3 W/MK. In contrast, HTCC manufacturing technology sintering temperature is slightly lower than AL2O3 sintering temperature, so the conductivity number is slightly lower too : 16-17 W/MK. Generally, DPC/DBC ceramic PCB has better/higher heat conductivity than LTCC/HTCC ceramic PCB.

Operating enviorment temperature

Operating enviorment temperature means the highest temperature that are used in the ceramic PCB manufacturing process. Let's the temperature goes higher, the manufacturing cost goes higher and yield goes lower.

HTCC technology requires temperature among 1300-1600 celsius degress depending on ceramic materials. LTCC/DBC technology requires temperature between 850-1000 celsius degress. Besides, either LTCC or HTCC require stack up before sintering, so each layer has a challenge of shrink ratio, the industry research are still finding a good way to solve it.

DBC technology has very precise requirements on temperature control, the working temperature must be among 1065~1085 degress and only in this case the copper layer will be mixed together with ceramic plate closely. If not, the yield will be very low. DPC technology only requires 250-350 degress for the production of ceramic PCB, it has totally avoided the damage from high temperature to the material and reduced manufacturing cost accordingly.

Technology of Circuit Printing

This mainly indicates to how the circuits are printed on the board. The chosen of printing method is quite important because it has direct impact on circuits precision, surface roughness, alighment accuracy, etc.

Both LTCC and HTCC adopts thick film printing technology for circuits printing. This method is restricted by screen tension and its circuits printed are relatively rough with imprecise alignment and with higher tolerance. Not to mention for multilayer ceramic PCB, the shrink ratio must be considered as an diffculty. Thus overall LTCC and HTCC has lower circuits printing quality.

For DBC circuits printing technology, it adopts the lithographic method with a restiction of copper thickness mininum 150~300um, therefore the circuits resolution quality max. is 150~300um accordingly.

For DPC circuits printing technology, it uses thin film method integrating with vacuum film plating and yellow light lithographic skill, so the circuits printed has a more precision quality and flatness. Later using electroplate method to increase the thickness of circuits with very few capability restriction. The resolution of DPC circuits can be 10~50um, so it can avoid the shrink ratio diffculty and screen tension problem.

Application of ceramic PCB

Normally the ceramic PCB differs in shapes when they are designed for different applications. For ceramic PCB made by LTCC technology, they are usually used in LED industry, bigger size/higher capacity and smaller size/lower capacity products. They often made with a concave and available to add a lead frame. The concave shape usually comes with simple adhesive and dispense sealing method, edges are the route for light reflections, however, restricted by LTCC itself, the board can't be made to very small size. Furtherly, with thick film technology, the resolution quality is not qualified to make high capacity/small size LED products.

HTCC technology are not widely used in LED applications, because HTCC requires enviorment 1300-1600 celsius degree in production, the manufacturing expense is higher. While the LED industry is seeking to reduce extremely in cost reduction, so it is not strange HTCC is not popular.

The other side, DBC/DPB ceramic board differ from HTCC/LTCC ceramic board not only in shapes, but also in packaging/sealing method. Both DPC and DBC are flat board design, it can be customized highly by customer requirements and cut to tiny size. With the help of Eutectic/polycrystalline and mature fluorescent powder coating technology, the LED illuminating efficency will be largely increased.

But as we stated above, the circuit resolution quality max. for DBC circuits boards is 150-300um, it is not enough for making small circuits. If adopting grinding method to lower copper layer thickness, the surface flatness will be diffcuit to control and extra cost will be needed. In the end DBC ceramic PCB are not suitable where high precision of circuits is required.

The ceramic PCB made with DPC circuit printing technology, as we stated above too, are using thin film lithography process, with a feature of precise circuits and surface flatness. It reduce the wire cut size significantly of LED, therefore to increase heat conductivity too.

Conclusions

We have explained and compared the manufacturing process, features and applications of varies ceramic PCB manufacturing technologies. DPC ceramic PCB enjoys the best capability and tecnology tolerance: trace width 10~50um or even smaller, flatness surface <0.3um and circuits alighment precision +/-1%, etc. It has totally avoid previous shortcoming of ceramic PCB making such as shrink ratio, screen tension, surface roughness and high cost. So we would say DPC ceramic PCB, judging from today's trend, is the most suitable choice for high capacity LED applications.

At Chee mau, we have the most advance ceramic PCB manufacturing technology, we welcome your inquiry anytime from anywhere at inquiry@cheemau.com

Comments